Step 1: Increasing Ventilation

By David Van der Vossen, PE

By David Van der Vossen, PE

Senior VP of Engineering

LEED AP BD+C, CGD

As we evaluate the lessons learned over the last year and evaluate the evolution of recommendations to minimize aerosol transmission rates of COVID-19, we start with the first step suggested by the CDC and ASHRAE of maximizing outdoor air ventilation to reduce indoor contaminants. (Reference 1—ASHRAE Position Document on Infections Aerosols) The primary goal is to dilute indoor contaminants and, in this case, dilute the concentration of COVID-19 aerosols. While no specific levels were provided by the CDC, doubling outside air ventilation rates from typically around 15% to 30% is feasible in many commercial situations. ASHRAE recommends that you first make sure you follow the ASHRAE standard for “Ventilation for Acceptable Indoor Air Quality.” (R2—ASHRAE Guidance for the Re-opening of Schools)

Currently, there are three recommendations regarding ventilation: (Reference 3—ASHRAE Technical Resources)

1) Disable CO2, occupancy controllers or demand control ventilation (DCV)

2) Maximize ventilation

3) Increase ventilation run times beyond occupied periods

Trade-offs

The trade-offs of drastic outdoor air ventilation increases are both energy efficiency and unit capacity. In existing systems, the increase of outside air utilizes system capacity intended for other building loads, potentially preventing the system from maintaining interior temperature setpoints. Humidity control is also challenged as the system may not handle the humidity load of the outside air, resulting in elevated humidity within the space.

Energy codes and standard design practices typically involve incorporating occupancy control systems to match the ventilation rate with the occupancy in a space. This is to ensure buildings are not over ventilating and are saving appropriate energy. One of the most common methods is to utilize CO2 sensors which are a representative measure of other indoor contaminants and of the occupancy in the space. By monitoring the CO2 systems, we can automatically adjust the amount of outdoor air to track occupants and keep overall indoor contaminants at an acceptable level.

Since we are trying to maximize outdoor air in the space, we do not want the CO2 sensors, occupancy controllers or other demand control ventilation products reducing the amount of outdoor air. (Reference 4—Centers for Disease Control, Ventilation in Buildings)

Therefore, the first step is to disable these systems and move to full ventilation based on occupancy. This can typically be done with a simple occupancy schedule. In this manner a building will receive full ventilation whenever it is scheduled to be occupied, rather than throttling it under partial occupancy.

Step 2: Increasing Ventilation Beyond Base Levels

The second step is to increase the ventilation beyond these base levels and increase it to the maximum extent possible. The amount of outdoor air we can provide through the HVAC system is typically limited by the overall capacity of the system. Eventually, if we continue to add outdoor air, we will lose control of the discharge temperature and the space temperature. For example, on a 95-degree day, every 1000 cubic feet per minute (cfm) of outdoor air will add a load of roughly five tons. Given that a system capacity is limited, we can only add a certain amount of outdoor air before we can no longer maintain the space setpoints. As temperatures vary so does the amount of outdoor air the system can handle.

There are several different approaches to ensure the capacity of the system is not exceeded. More advanced control systems can be programmed to adjust throughout the day to maximize the outdoor air at any given moment. The most rudimentary strategy is to evaluate the system capacity and develop a schedule of outdoor temperatures and associated percentages of outdoor air the system can handle. As the system hits more extreme temperatures (either hot or cold) the amount of outdoor air would decrease, and as the outdoor temperatures become more moderate, the more the outdoor air can be increased. This schedule can then be used to manually change ventilation amounts based on the daily predicted temperature or can be tied to an outdoor air sensor to vary the outdoor air volume as the temperature changes throughout the day.

Since a system may have additional capacity beyond what is calculated and the internal loads may be lower than assumed because of partial occupancy, the most ideal approach is to look at discharge temperature. Systems are typically designed to have a standard discharge temperature. For example, many utilize 55 degrees in cooling. A control strategy can be implemented that tracks discharge temperature throughout the day. This would increase outdoor air if the discharge temperature were being maintained and when discharge temperature was not being maintained, it would start to reduce the amount of outdoor air. In this manor the outdoor air could be maximized at all times based on actual system capacity.

Step 3: Extending Ventilation Run Times

The third action step regarding ventilation is to extend ventilation run times, also referred to as purge cycles. In this area ASHRAE and the CDC have both evolved and differed in their direction. The CDC originally recommended running the ventilation system 24/7 and now have moved to a position of two hours before and after occupancy. (Reference 5—CDC Ventilation in Schools and Childcare Programs) ASHRAE originally recommended a two-hour purge cycle before and after occupancy. ASHRAE’s current recommendation is to run purge cycles that correlate with flushing the space with outdoor air three times. (Reference 6—ASHRAE Technical Resources: HVAC Systems) The length of this purge cycle will change depending on building and what percentage of outdoor air is being run.

As these steps are implemented, one should evaluate the system design and controls to ensure that the outdoor air is indeed delivered to the occupied spaces and not just the central equipment. Many systems are variable air volume systems (VAV) or otherwise use some sort of control dampers to vary airflow to a space. These systems can limit the amount of air from the central system that is being delivered to the space and as a result reduce the amount of outdoor air being delivered to occupied spaces. Controls should be evaluated and adjusted to maximize air delivery. This may come at a trade off for space comfort. Strategies include adjusting the supply air temperature to result in longer periods in which the damper stays open and raising the minimum set point on a box which could result in overcooling or more reheat being run at the VAV boxes thereby using more energy. (Reheat is a heater within the VAV box that provides local zone heating) During the pandemic, these methods should be prioritized and as the pandemic wains, more traditional controls should be reestablished.

There are a handful of side notes to the three steps outlined above. Many of our buildings, especially older schools for instance, may have operable windows. In the case of schools, many have been fixed shut for security or maintenance reasons. These should be put back in service and utilized whenever practical. While not as consistent, natural ventilation has shown to be very effective. (Reference 7—The Bemidji Pioneer, News MD)

Energy recovery wheels have been brought into question due to the fact they have a certain amount of exhaust air that is recirculated into the supply stream. Since the percentage is relatively low and the air being exhausted is the same air that was in the space, it is recommended that the energy wheels remain enabled so ventilation rates can be maximized. (Reference 8—ASHRAE Practical Guidance for Epidemic Operation of Energy Recovery Ventilation Systems)

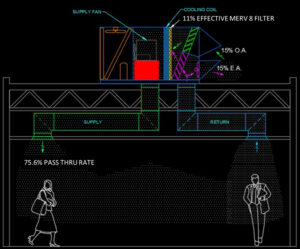

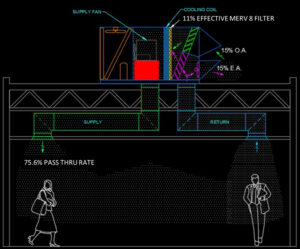

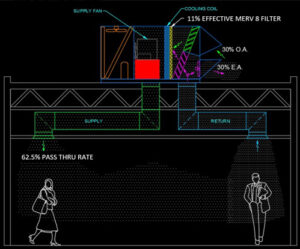

If we implement the strategies outlined above on our sample project that was referenced in last week’s blog, we can start to see an improvement in reducing the pass-through rate of the virus. Our original starting point was 15% outdoor air and a MERV 8 filter which resulted in a pass-through rate of 75.6%.

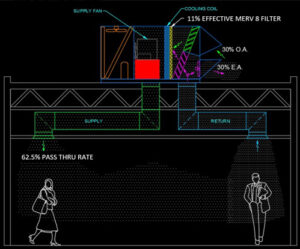

If on a particular afternoon the outdoor temperature is 80 degrees, we can run 30% outdoor air. Our pass-through rate drops to 62.5%, which means we have eliminated an additional 13.1% of the virus particles every time the air goes through our HVAC unit. Typically, systems are designed such that the whole room volume passes thru the HVAC unit four to six times per hour, eliminating an additional 13.1% of the virus particles from the air. It’s important to remember that if the carrier is in the space, they will also continue to add virus particles to the air.

It is also important to note that we want to maximize the outdoor air at all times based on the outdoor temperatures and the capacity of the system. For instance, if the temperature drops several degrees (say to 75 degrees) and we can go from running 30% outdoor air up to 50% outdoor air, our pass-through rate drops all the way down to 44.5%. So, it is critical that we push as much outdoor air as possible at all occupied times.

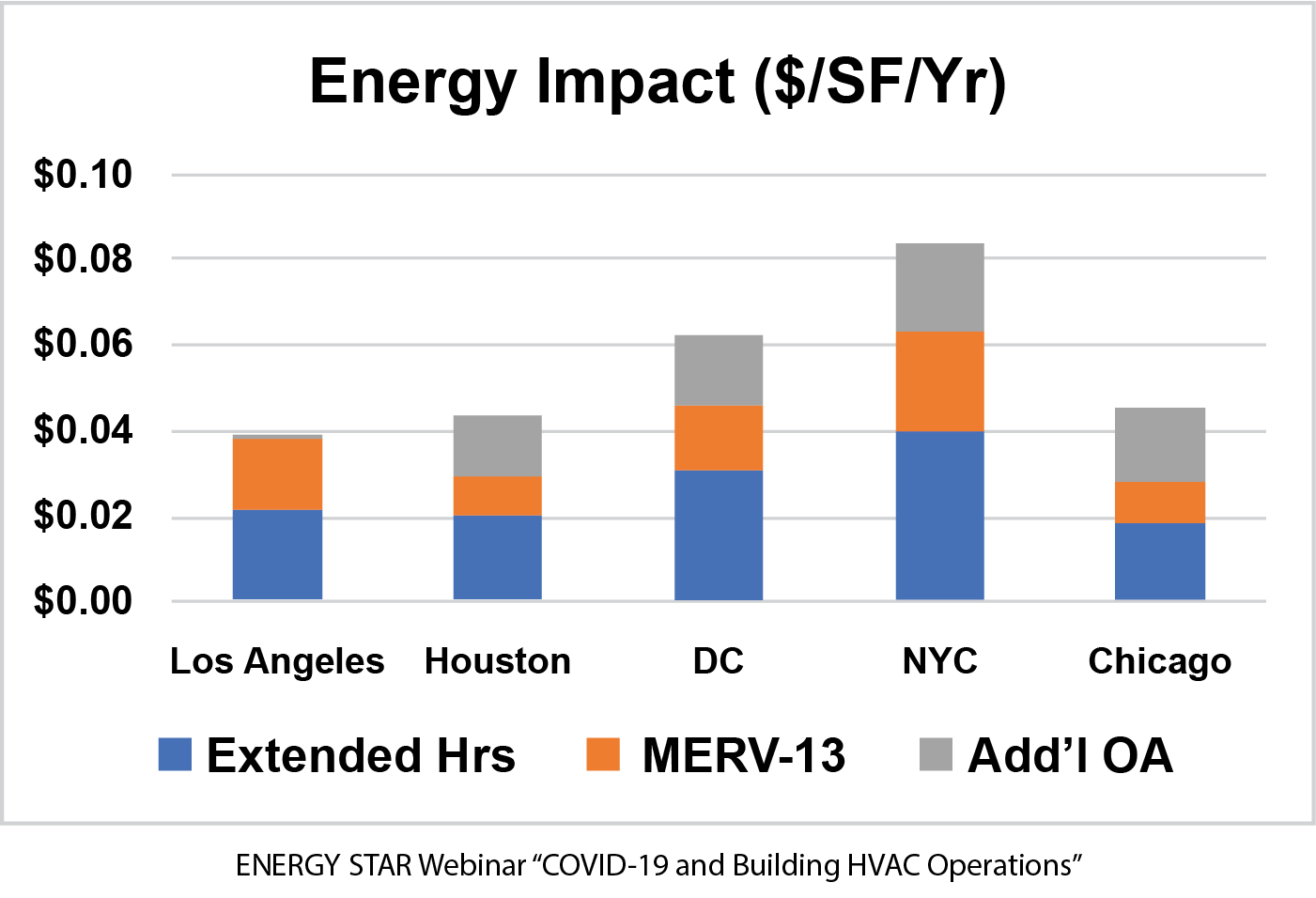

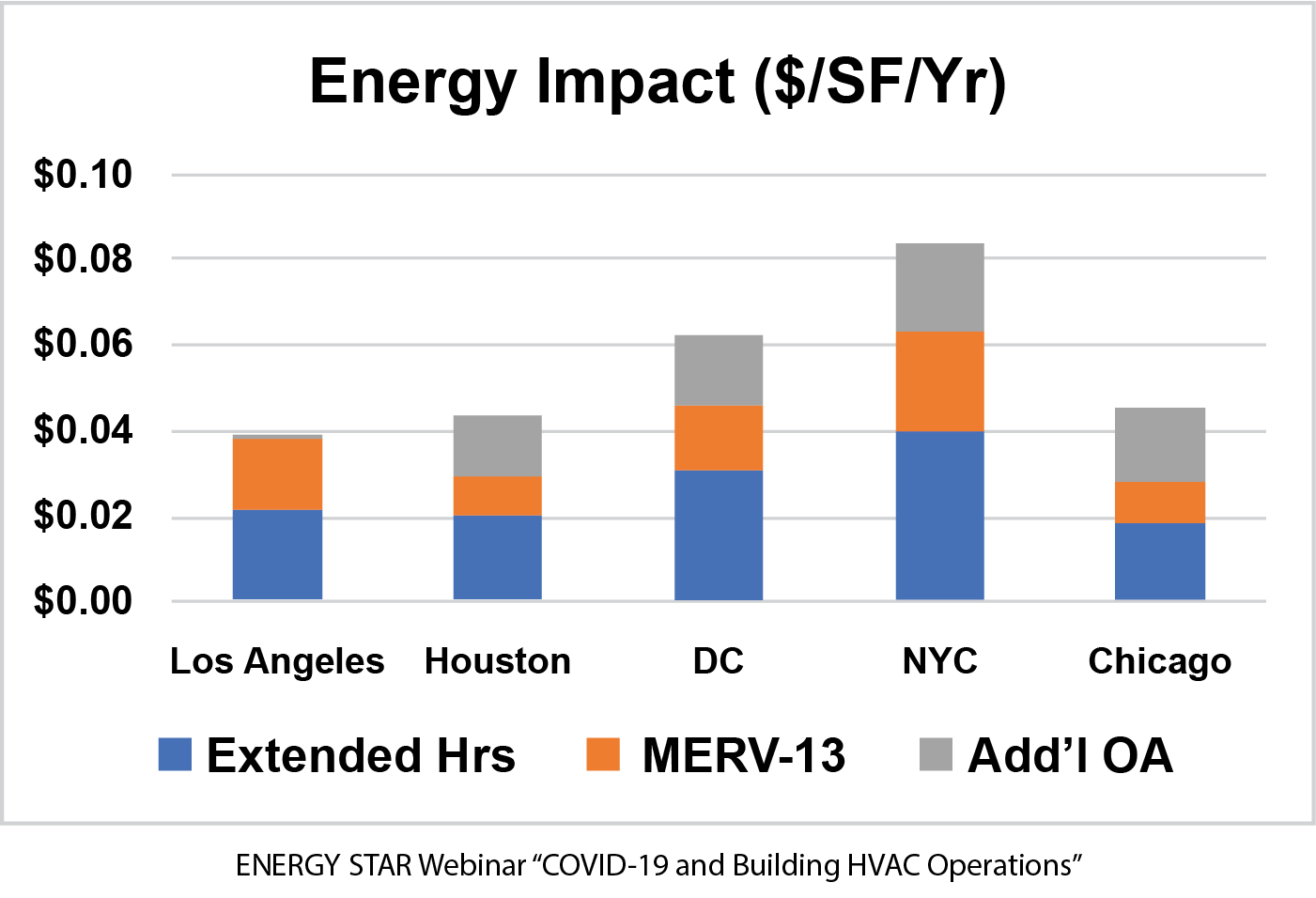

Costs have also been examined as it relates to additional volume of outdoor air. Depending on which market, costs can range from about $0.02/SF/YR to about $0.04/SF/YR based on an assumption of an average increase in outdoor air of 50%. The cost for operating the ventilation two hours before and after normal occupied period was also examined and found to run from virtually no additional cost in Los Angeles to $0.02/SF/YR in several other markets.

Most buildings can implement some or all the ventilation strategies outlined above. This is the first step in increasing the health of our indoor spaces. In the long run, there will be a new balance point between the health of indoor spaces and the financial and energy impacts of increased outdoor air.

Engineering Tomorrow

At Allen + Shariff, we believe in providing innovative and efficient MEP engineering solutions to our clients. Contact us for more information on our ongoing blog series, to participate in a registered AIA seminar, or learn more about how you can partner with our team.

Contact Dave Van der Vossen at 910-218-3856 for details.

Step 1: Increasing Ventilation

By David Van der Vossen, PE

By David Van der Vossen, PE

Senior VP of Engineering

LEED AP BD+C, CGD

As we evaluate the lessons learned over the last year and evaluate the evolution of recommendations to minimize aerosol transmission rates of COVID-19, we start with the first step suggested by the CDC and ASHRAE of maximizing outdoor air ventilation to reduce indoor contaminants. (Reference 1—ASHRAE Position Document on Infections Aerosols) The primary goal is to dilute indoor contaminants and, in this case, dilute the concentration of COVID-19 aerosols. While no specific levels were provided by the CDC, doubling outside air ventilation rates from typically around 15% to 30% is feasible in many commercial situations. ASHRAE recommends that you first make sure you follow the ASHRAE standard for “Ventilation for Acceptable Indoor Air Quality.” (R2—ASHRAE Guidance for the Re-opening of Schools)

Currently, there are three recommendations regarding ventilation: (Reference 3—ASHRAE Technical Resources)

1) Disable CO2, occupancy controllers or demand control ventilation (DCV)

2) Maximize ventilation

3) Increase ventilation run times beyond occupied periods

Trade-offs

The trade-offs of drastic outdoor air ventilation increases are both energy efficiency and unit capacity. In existing systems, the increase of outside air utilizes system capacity intended for other building loads, potentially preventing the system from maintaining interior temperature setpoints. Humidity control is also challenged as the system may not handle the humidity load of the outside air, resulting in elevated humidity within the space.

Energy codes and standard design practices typically involve incorporating occupancy control systems to match the ventilation rate with the occupancy in a space. This is to ensure buildings are not over ventilating and are saving appropriate energy. One of the most common methods is to utilize CO2 sensors which are a representative measure of other indoor contaminants and of the occupancy in the space. By monitoring the CO2 systems, we can automatically adjust the amount of outdoor air to track occupants and keep overall indoor contaminants at an acceptable level.

Since we are trying to maximize outdoor air in the space, we do not want the CO2 sensors, occupancy controllers or other demand control ventilation products reducing the amount of outdoor air. (Reference 4—Centers for Disease Control, Ventilation in Buildings)

Therefore, the first step is to disable these systems and move to full ventilation based on occupancy. This can typically be done with a simple occupancy schedule. In this manner a building will receive full ventilation whenever it is scheduled to be occupied, rather than throttling it under partial occupancy.

Step 2: Increasing Ventilation Beyond Base Levels

The second step is to increase the ventilation beyond these base levels and increase it to the maximum extent possible. The amount of outdoor air we can provide through the HVAC system is typically limited by the overall capacity of the system. Eventually, if we continue to add outdoor air, we will lose control of the discharge temperature and the space temperature. For example, on a 95-degree day, every 1000 cubic feet per minute (cfm) of outdoor air will add a load of roughly five tons. Given that a system capacity is limited, we can only add a certain amount of outdoor air before we can no longer maintain the space setpoints. As temperatures vary so does the amount of outdoor air the system can handle.

There are several different approaches to ensure the capacity of the system is not exceeded. More advanced control systems can be programmed to adjust throughout the day to maximize the outdoor air at any given moment. The most rudimentary strategy is to evaluate the system capacity and develop a schedule of outdoor temperatures and associated percentages of outdoor air the system can handle. As the system hits more extreme temperatures (either hot or cold) the amount of outdoor air would decrease, and as the outdoor temperatures become more moderate, the more the outdoor air can be increased. This schedule can then be used to manually change ventilation amounts based on the daily predicted temperature or can be tied to an outdoor air sensor to vary the outdoor air volume as the temperature changes throughout the day.

Since a system may have additional capacity beyond what is calculated and the internal loads may be lower than assumed because of partial occupancy, the most ideal approach is to look at discharge temperature. Systems are typically designed to have a standard discharge temperature. For example, many utilize 55 degrees in cooling. A control strategy can be implemented that tracks discharge temperature throughout the day. This would increase outdoor air if the discharge temperature were being maintained and when discharge temperature was not being maintained, it would start to reduce the amount of outdoor air. In this manor the outdoor air could be maximized at all times based on actual system capacity.

Step 3: Extending Ventilation Run Times

The third action step regarding ventilation is to extend ventilation run times, also referred to as purge cycles. In this area ASHRAE and the CDC have both evolved and differed in their direction. The CDC originally recommended running the ventilation system 24/7 and now have moved to a position of two hours before and after occupancy. (Reference 5—CDC Ventilation in Schools and Childcare Programs) ASHRAE originally recommended a two-hour purge cycle before and after occupancy. ASHRAE’s current recommendation is to run purge cycles that correlate with flushing the space with outdoor air three times. (Reference 6—ASHRAE Technical Resources: HVAC Systems) The length of this purge cycle will change depending on building and what percentage of outdoor air is being run.

As these steps are implemented, one should evaluate the system design and controls to ensure that the outdoor air is indeed delivered to the occupied spaces and not just the central equipment. Many systems are variable air volume systems (VAV) or otherwise use some sort of control dampers to vary airflow to a space. These systems can limit the amount of air from the central system that is being delivered to the space and as a result reduce the amount of outdoor air being delivered to occupied spaces. Controls should be evaluated and adjusted to maximize air delivery. This may come at a trade off for space comfort. Strategies include adjusting the supply air temperature to result in longer periods in which the damper stays open and raising the minimum set point on a box which could result in overcooling or more reheat being run at the VAV boxes thereby using more energy. (Reheat is a heater within the VAV box that provides local zone heating) During the pandemic, these methods should be prioritized and as the pandemic wains, more traditional controls should be reestablished.

There are a handful of side notes to the three steps outlined above. Many of our buildings, especially older schools for instance, may have operable windows. In the case of schools, many have been fixed shut for security or maintenance reasons. These should be put back in service and utilized whenever practical. While not as consistent, natural ventilation has shown to be very effective. (Reference 7—The Bemidji Pioneer, News MD)

Energy recovery wheels have been brought into question due to the fact they have a certain amount of exhaust air that is recirculated into the supply stream. Since the percentage is relatively low and the air being exhausted is the same air that was in the space, it is recommended that the energy wheels remain enabled so ventilation rates can be maximized. (Reference 8—ASHRAE Practical Guidance for Epidemic Operation of Energy Recovery Ventilation Systems)

If we implement the strategies outlined above on our sample project that was referenced in last week’s blog, we can start to see an improvement in reducing the pass-through rate of the virus. Our original starting point was 15% outdoor air and a MERV 8 filter which resulted in a pass-through rate of 75.6%.

If on a particular afternoon the outdoor temperature is 80 degrees, we can run 30% outdoor air. Our pass-through rate drops to 62.5%, which means we have eliminated an additional 13.1% of the virus particles every time the air goes through our HVAC unit. Typically, systems are designed such that the whole room volume passes thru the HVAC unit four to six times per hour, eliminating an additional 13.1% of the virus particles from the air. It’s important to remember that if the carrier is in the space, they will also continue to add virus particles to the air.

It is also important to note that we want to maximize the outdoor air at all times based on the outdoor temperatures and the capacity of the system. For instance, if the temperature drops several degrees (say to 75 degrees) and we can go from running 30% outdoor air up to 50% outdoor air, our pass-through rate drops all the way down to 44.5%. So, it is critical that we push as much outdoor air as possible at all occupied times.

Costs have also been examined as it relates to additional volume of outdoor air. Depending on which market, costs can range from about $0.02/SF/YR to about $0.04/SF/YR based on an assumption of an average increase in outdoor air of 50%. The cost for operating the ventilation two hours before and after normal occupied period was also examined and found to run from virtually no additional cost in Los Angeles to $0.02/SF/YR in several other markets.

Most buildings can implement some or all the ventilation strategies outlined above. This is the first step in increasing the health of our indoor spaces. In the long run, there will be a new balance point between the health of indoor spaces and the financial and energy impacts of increased outdoor air.

Engineering Tomorrow

At Allen + Shariff, we believe in providing innovative and efficient MEP engineering solutions to our clients. Contact us for more information on our ongoing blog series, to participate in a registered AIA seminar, or learn more about how you can partner with our team.

Contact Dave Van der Vossen at 910-218-3856 for details.