By David Van der Vossen, PE

By David Van der Vossen, PE

Senior VP of Engineering

LEED AP BD+C, CGD

Increasing the Level of HVAC Filters

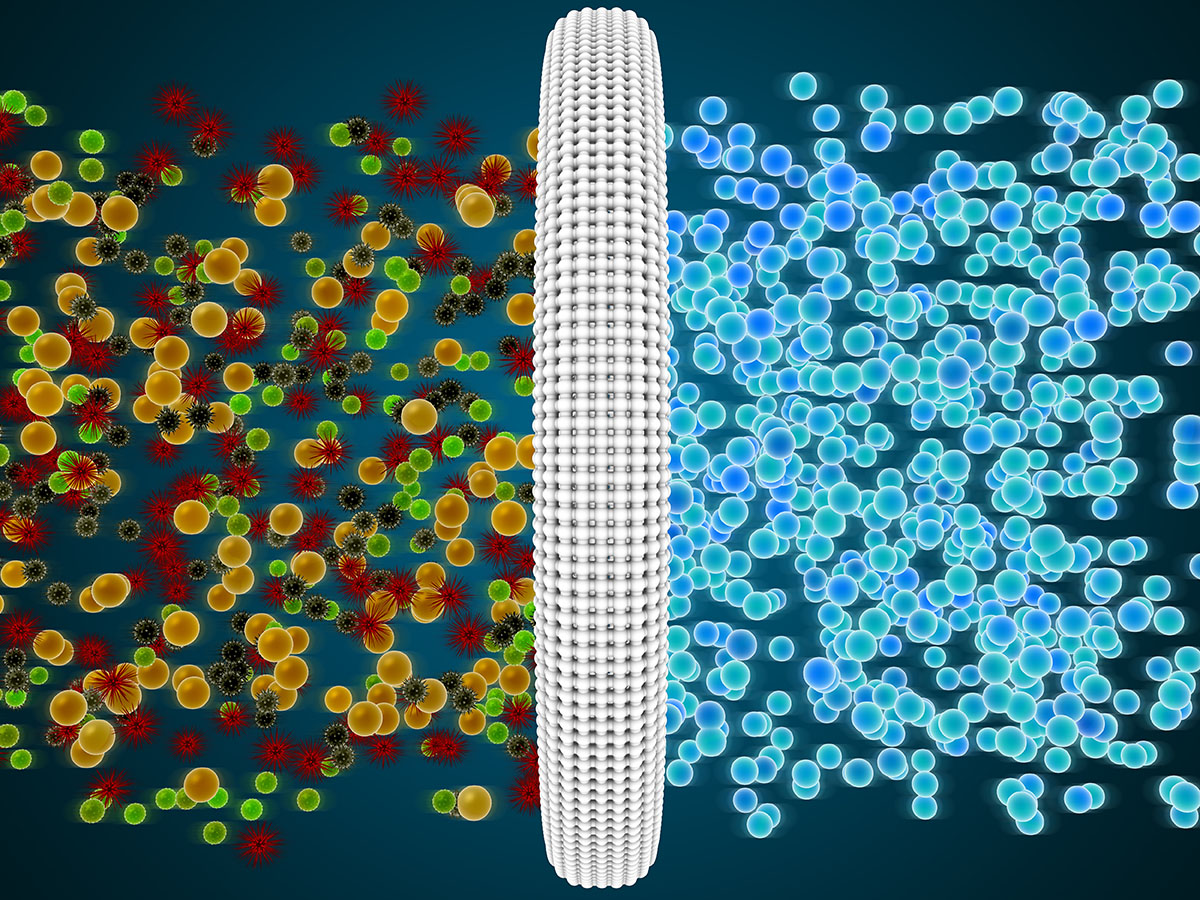

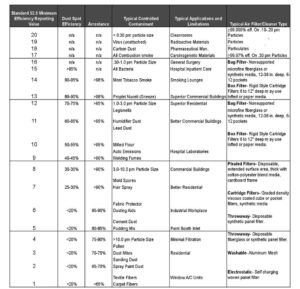

The second step recommended by ASHRAE and the CDC to control aerosol transmission of airborne viruses such as COVID-19 is to increase the level of filters being used in HVAC systems. Most existing and legacy HVAC systems use MERV 8 filters. Newer and larger commercial systems may utilize a MERV 11 or possibly a MERV 13 filter. For our example we will assume a standard 20-ton rooftop using a common MERV 8 filter.

MERV Filters

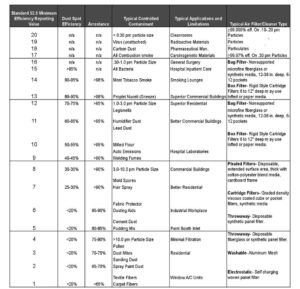

First, what is MERV? MERV is an acronym for the Minimum Efficiency Rating Value. It is an ASHRAE standard established in 1987 to report the effectiveness of filters; the most recent update was done in 2017. Standard 52.2-2017—American Society of Heating, Refrigerating and Air-Conditioning Engineers (iwrapper.com)

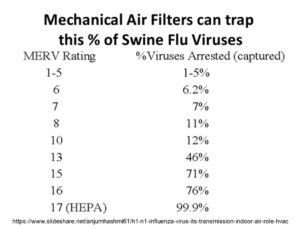

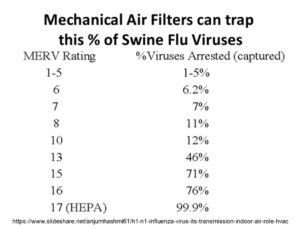

Based on a SARS study, MERV 8 filters were tested to be 11% effective against the SARS virus. COVID-19 is similar in size at 0.125 micrometers.

MERV 8 Filters and COVID-19 Particles

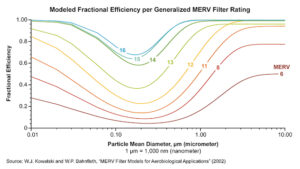

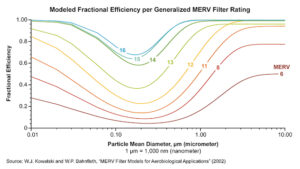

We can also reference plotted values of effectiveness of different filters against particles of different mean sizes. For COVID-19, we would chart 0.125 micrometers on the x or bottom axis of the MERV 8 filter curve—the pink colored line in the chart below. Carrying it across to the y or left axis it plots out at roughly 12% effectiveness. We conservatively have used 11% for our analysis based on the SARS study.

Filtration / Disinfection (ashrae.org)

Can My HVAC System Handle

a Higher MERV Filter Rating?

ASHRAE and the CDC both recommend increasing our MERV rating with a goal of a MERV 13. However, if we can practically utilize a higher rated filter, we should, or if we can’t make it to a MERV 13 filter, we should utilize the highest filter that will work with our HVAC system. Each step up improves the effectiveness rate.

When determining which filters can be utilized, we must analyze the size and strength of our supply fan in comparison to the amount of resistance in our HVAC system. Higher rated MERV filters have more resistance to the airflow going through them. As we increase to higher level MERV ratings, we add resistance on to our HVAC system. An analysis needs to be done to ensure that a filter is not selected too high such that it chokes down the airflow in the system. This reduced airflow is counter to the increased ventilation rates in our first step, which can impact comfort and—in extreme cases—cause units to shut off due to high head pressure in the refrigeration circuit. A balance must be reached so that the highest rated filter reasonably possibly is utilized without negatively affecting airflows.

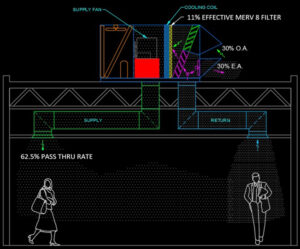

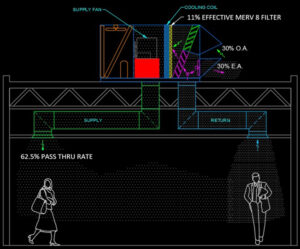

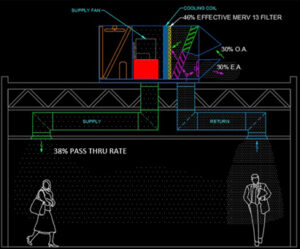

If we go back and look at our sample project, our starting point where we left off from the last, we have already increased the outdoor air from 15% to 30%, dropping the pass-through rate from 75.6% to 62.5%. The unit has a standard MERV 8 filter installed.

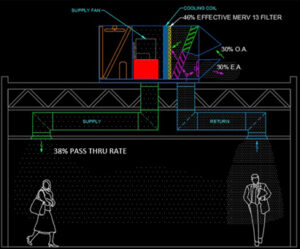

If we are able increase our filter to a MERV 13, we jump to an effectiveness of 46%. This is over four times more effective than our starting point of MERV 8, dropping the pass-through rate down to 38% simply by increasing our outdoor air and replacing the filters.

Will HEPA Filters Work?

There has been much discussion related to HEPA filters. Unfortunately, HEPA filters are not a practical solution in most applications. The extreme pressure drop through the filters is typically too much for standard systems to handle. Most hospitals use MERV 15 filters through the bulk of their facility, reserving HEPA filters for LAB, Surgery Areas and ICU spaces. Smaller in room or above ceiling HEPA fan filter units may be a possibility. When we compare the impact of a 500-cfm room-based HEPA filter unit versus installing MERV 13 filters in a 10-ton air handler serving the same space, four times the number of virus particles will be captured with the larger air handler even at the lower filter rate simply because of the significantly larger volume of air it is processing. Whenever possible, the main central equipment should be addressed first with fallback solutions of room-based filtering equipment being implemented when central equipment cannot or when there is a higher risk space. The other issue with room-based equipment can be the sound of the fan located in the space; at full speed most of these units are around 60db, which can be very distracting.

Correct Filter Installation is Key to Effectiveness

Correct installation of filters is critical for proper operation and effectiveness. A 1/2“gap in between MERV 13 filters has been shown to derate the filters down to MERV 8. The picture below demonstrates one easy solution to reduce bypass by taping filters to each other during installation. Gaskets and other sealing mechanisms should be checked for serviceability.

Due to the limited increase in costs, the effectiveness against pathogens and allergens, and other drivers such as USGBC’s LEED rating system points for increasing filters, it is very likely that the industry standard will move towards these higher rated filters.

Engineering Tomorrow

At Allen + Shariff, we believe in providing innovative and efficient MEP engineering solutions to our clients. Contact us for more information on our ongoing blog series, to participate in a registered AIA seminar, or learn more about how you can partner with our team.

Contact Dave Van der Vossen at 910-218-3856 for details.

By David Van der Vossen, PE

By David Van der Vossen, PE

Senior VP of Engineering

LEED AP BD+C, CGD

Increasing the Level of HVAC Filters

The second step recommended by ASHRAE and the CDC to control aerosol transmission of airborne viruses such as COVID-19 is to increase the level of filters being used in HVAC systems. Most existing and legacy HVAC systems use MERV 8 filters. Newer and larger commercial systems may utilize a MERV 11 or possibly a MERV 13 filter. For our example we will assume a standard 20-ton rooftop using a common MERV 8 filter.

MERV Filters

First, what is MERV? MERV is an acronym for the Minimum Efficiency Rating Value. It is an ASHRAE standard established in 1987 to report the effectiveness of filters; the most recent update was done in 2017. Standard 52.2-2017—American Society of Heating, Refrigerating and Air-Conditioning Engineers (iwrapper.com)

Based on a SARS study, MERV 8 filters were tested to be 11% effective against the SARS virus. COVID-19 is similar in size at 0.125 micrometers.

MERV 8 Filters and COVID-19 Particles

We can also reference plotted values of effectiveness of different filters against particles of different mean sizes. For COVID-19, we would chart 0.125 micrometers on the x or bottom axis of the MERV 8 filter curve—the pink colored line in the chart below. Carrying it across to the y or left axis it plots out at roughly 12% effectiveness. We conservatively have used 11% for our analysis based on the SARS study.

Filtration / Disinfection (ashrae.org)

Can My HVAC System Handle

a Higher MERV Filter Rating?

ASHRAE and the CDC both recommend increasing our MERV rating with a goal of a MERV 13. However, if we can practically utilize a higher rated filter, we should, or if we can’t make it to a MERV 13 filter, we should utilize the highest filter that will work with our HVAC system. Each step up improves the effectiveness rate.

When determining which filters can be utilized, we must analyze the size and strength of our supply fan in comparison to the amount of resistance in our HVAC system. Higher rated MERV filters have more resistance to the airflow going through them. As we increase to higher level MERV ratings, we add resistance on to our HVAC system. An analysis needs to be done to ensure that a filter is not selected too high such that it chokes down the airflow in the system. This reduced airflow is counter to the increased ventilation rates in our first step, which can impact comfort and—in extreme cases—cause units to shut off due to high head pressure in the refrigeration circuit. A balance must be reached so that the highest rated filter reasonably possibly is utilized without negatively affecting airflows.

If we go back and look at our sample project, our starting point where we left off from the last, we have already increased the outdoor air from 15% to 30%, dropping the pass-through rate from 75.6% to 62.5%. The unit has a standard MERV 8 filter installed.

If we are able increase our filter to a MERV 13, we jump to an effectiveness of 46%. This is over four times more effective than our starting point of MERV 8, dropping the pass-through rate down to 38% simply by increasing our outdoor air and replacing the filters.

Will HEPA Filters Work?

There has been much discussion related to HEPA filters. Unfortunately, HEPA filters are not a practical solution in most applications. The extreme pressure drop through the filters is typically too much for standard systems to handle. Most hospitals use MERV 15 filters through the bulk of their facility, reserving HEPA filters for LAB, Surgery Areas and ICU spaces. Smaller in room or above ceiling HEPA fan filter units may be a possibility. When we compare the impact of a 500-cfm room-based HEPA filter unit versus installing MERV 13 filters in a 10-ton air handler serving the same space, four times the number of virus particles will be captured with the larger air handler even at the lower filter rate simply because of the significantly larger volume of air it is processing. Whenever possible, the main central equipment should be addressed first with fallback solutions of room-based filtering equipment being implemented when central equipment cannot or when there is a higher risk space. The other issue with room-based equipment can be the sound of the fan located in the space; at full speed most of these units are around 60db, which can be very distracting.

Correct Filter Installation is Key to Effectiveness

Correct installation of filters is critical for proper operation and effectiveness. A 1/2“gap in between MERV 13 filters has been shown to derate the filters down to MERV 8. The picture below demonstrates one easy solution to reduce bypass by taping filters to each other during installation. Gaskets and other sealing mechanisms should be checked for serviceability.

Due to the limited increase in costs, the effectiveness against pathogens and allergens, and other drivers such as USGBC’s LEED rating system points for increasing filters, it is very likely that the industry standard will move towards these higher rated filters.

Engineering Tomorrow

At Allen + Shariff, we believe in providing innovative and efficient MEP engineering solutions to our clients. Contact us for more information on our ongoing blog series, to participate in a registered AIA seminar, or learn more about how you can partner with our team.

Contact Dave Van der Vossen at 910-218-3856 for details.